In today's industrial automation landscape, servo motor driver plays a critical role in ensuring high-precision motion control for robotics, CNC machines, and automated production systems. As a key supplier of industrial automation components, Viyork specializes in providing servo motor driver from leading global brands such as Yaskawa, Mitsubishi, Siemens, and ABB. These high-performance drives are designed to optimize efficiency, reduce energy consumption, and provide stable control in demanding industrial environments.

Servo motor driver acts as the brain of motion control systems, converting electrical signals into precise mechanical movement. Unlike standard motor controllers, servo drives regulate speed, torque, and position with exceptional accuracy, making them indispensable in applications such as assembly lines, semiconductor manufacturing, and packaging automation. With rapid advancements in Industry 4.0, the demand for high-quality servo motor driver continues to grow, ensuring smooth, responsive, and error-free operation in complex machinery.

While both servo motor driver and variable frequency drives (VFDs) control motor movements, they serve different purposes. Servo motor driver excels in applications requiring ultra-precise positioning, such as robotic arms and CNC machines, thanks to their closed-loop feedback systems. On the other hand, VFDs are better suited for speed control in conveyor belts and pumps, where extreme precision is not as critical. Companies seeking high-performance motion control should carefully evaluate their operational needs before choosing between these two solutions.

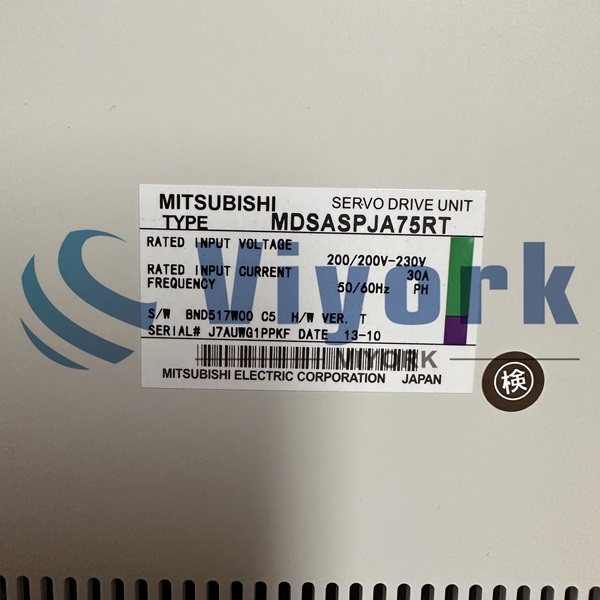

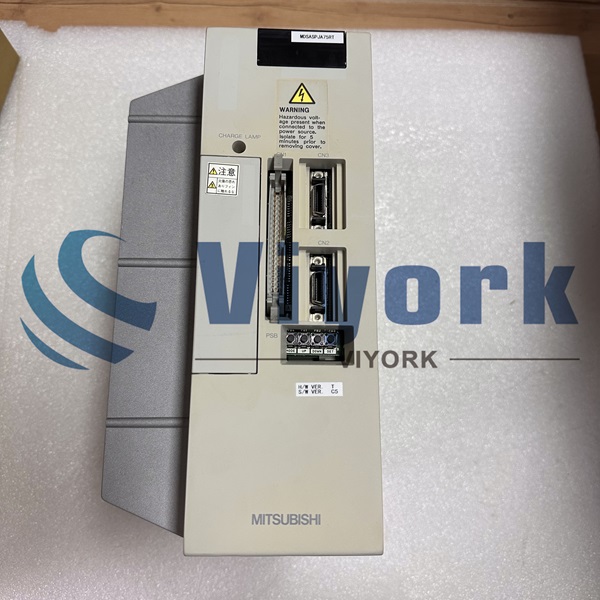

Selecting the right servo motor driver requires careful consideration of several factors. First, feedback resolution is crucial—whether the system uses encoders, resolvers, or Hall-effect sensors for real-time corrections. Additionally, communication protocols such as EtherCAT, PROFIBUS, or CANopen determine compatibility with existing automation networks. Another important aspect is overload protection, preventing damage from sudden mechanical stress. Brands available at Viyork, including Yaskawa and Mitsubishi, offer robust servo drives designed to meet these demanding performance criteria.

The versatility of servo motor driver makes them essential across multiple industries. In robotics, they enable precise articulation of robotic arms, ensuring smooth pick-and-place operations. In packaging automation, servo-controlled systems maintain consistent speed and positioning for filling and sealing processes. Additionally, industries such as aerospace and automotive manufacturing rely on servo-driven CNC machines for high-tolerance machining operations. With expanding automation needs, servo motor driver continues to shape the future of smart manufacturing.

As automation systems become increasingly sophisticated, selecting the best servo motor driver is critical for optimizing performance and efficiency. With access to leading brands and expert technical support, Viyork helps businesses integrate reliable servo solutions into their automation workflows. Whether upgrading an existing control system or designing a new automation setup, Viyork ensures access to premium servo drives that enhance productivity and precision.

By partnering with Viyork, industries gain the advantage of top-tier automation components, ensuring seamless and future-ready motion control solutions.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China