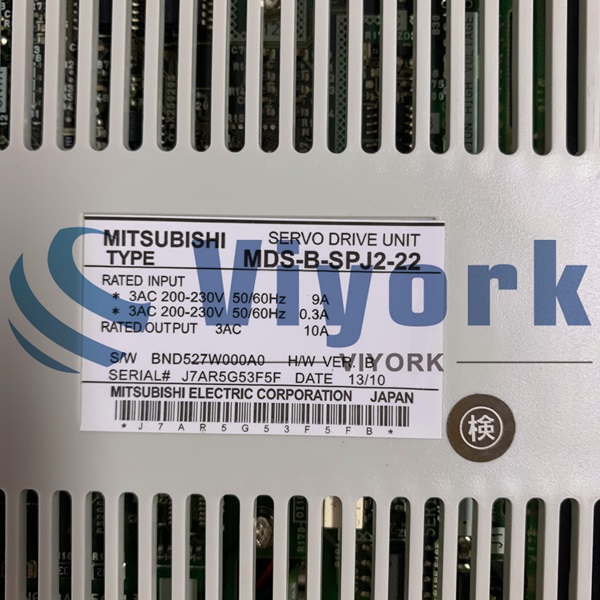

As industrial automation evolves, the demand for high performance servo drives continues to grow, enabling machines to achieve greater precision, efficiency, and speed. Viyork, a trusted supplier under Shenzhen Weiyousheng Technology Co., Ltd., specializes in distributing top-tier automation components, including advanced servo drives from Mitsubishi, Yaskawa, Siemens, and ABB. With rapid expansion across China and global markets, Viyork provides industrial solutions that enhance productivity and reliability. Their selection of high performance servo drives ensures optimal motion control for robotics, CNC machinery, and factory automation systems.

Standard servo drives meet basic motion control requirements, but high performance servo drive pushes the boundaries of speed, accuracy, and dynamic response. These advanced drives integrate real-time adaptive tuning, enabling them to adjust automatically to changing load conditions while maintaining precise control. Unlike standard models, high performance servo drive minimizes torque ripple and vibration, ensuring smoother operation in applications such as robotics and CNC machining.

Additionally, high performance servo drive compatibility enhances system responsiveness, making them ideal for automated production environments where microseconds matter. Viyork's portfolio includes high performance servo drive from Mitsubishi and ABB, delivering reliability in demanding industrial applications.

To better understand the advantages of high performance servo drive, here's a comparison table highlighting their superior capabilities:

Feature | High Performance Servo Drive | Standard Servo Drive |

Control Precision | Sub-micron positioning accuracy | Lower resolution |

Dynamic Response | Ultra-fast acceleration/deceleration | Moderate response time |

Energy Efficiency | Regenerative braking reduces power loss | No energy recovery system |

Vibration Control | Advanced algorithms minimize resonance | Limited damping capabilities |

Integration | Compatible with PLCs, DCS, and motion controllers | May require additional interfaces |

High performance servo drive excels in applications where speed, precision, and real-time adjustments are crucial. Viyork's solutions, sourced from Yaskawa and Siemens, ensure industrial machines operate with minimal downtime and maximum efficiency.

Choosing the right high performance servo drive requires evaluating critical specifications to match application demands. Torque control accuracy is fundamental, particularly in robotics and CNC machinery, where slight deviations can affect output quality. High dynamic response is another essential factor; drives with rapid acceleration ensure faster production cycles while maintaining stability under varying loads.

Communication compatibility should not be overlooked—modern industries rely on EtherCAT and PROFINET protocols for real-time data exchange between drives and control systems. Additionally, adaptive tuning capabilities ensure optimal performance even when mechanical conditions change, reducing the need for manual recalibration.

Viyork supplies high performance servo drive from ABB and GE Fanuc, offering flexible configurations for different automation needs. Whether upgrading existing systems or implementing new solutions, their drives enhance system precision and energy efficiency.

High performance servo drive is at the core of modern smart factories, driving automation advancements in semiconductor manufacturing, automotive assembly, and packaging lines. In robotics, these drives enable high-speed pick-and-place operations with micron-level repeatability. CNC machines benefit from high-performance servo drives' tight speed regulation, ensuring perfect surface finishes even at extreme cutting speeds.

Moreover, industries utilizing Servo Presses and Automated Guided Vehicles (AGVs) depend on high performance servo drive for predictive motion control and energy-efficient braking. Viyork partners with top automation brands, ensuring customers access servo drives that meet the stringent demands of Industry 4.0 environments.

Integrating a high performance servo drive into an automation system requires proper tuning, load matching, and network configuration. First, feedforward control should be enabled to reduce following errors in high-speed applications. Second, inertia ratio compensation ensures stability when handling varying mechanical loads, preventing unwanted vibrations.

Using servo drives with built-in condition monitoring helps detect potential faults before they cause downtime, improving overall system reliability. Viyork's servo drive solutions, designed for Yaskawa and Schneider systems, support predictive maintenance features that minimize unplanned interruptions.

By pairing high performance servo drive with Viyork's expert support, industries worldwide achieve faster throughput, better energy efficiency, and superior motion control.

The automation industry continues to demand higher precision and smarter control, making high performance servo drive indispensable in robotics, CNC, and smart manufacturing. Viyork delivers industry-leading servo drives from Mitsubishi, ABB, and Siemens, empowering businesses to maximize productivity while reducing operational costs.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China