What is servo motor controller? The servo motor controller is a key device in the numerical control system and other related mechanical control fields. Generally, the servo motor is controlled by three methods of position, speed and torque to achieve high-precision transmission system positioning. Servo control related technology has become an important reference for the national equipment technology level.

1. Installation in the electrical control cabinet

Due to the heating of the electrical equipment inside the air control cabinet and the heat dissipation conditions in the control cabinet, the temperature around the ac servo drive will continue to rise. Therefore, considering the cooling of the drive and the configuration in the control cabinet, ensure that the temperature around the servo drive is below 55°C , the relative humidity is below 90%. The long-term safe working temperature is below 45℃.

2. There is a heating device near the servo drive

Servo drives work under high temperature conditions, which will significantly shorten their life and cause failures. Therefore, it should be ensured that the ambient temperature of the servo driver is below 55 °C under the conditions of thermal convection and thermal radiation.

3. There is vibration equipment near the servo drive

Use various anti-vibration measures to ensure that the servo drive is not affected by vibration, and the vibration is guaranteed to be below 0.5g (4.9m/s).

4. Servo drives are used in harsh environments

When the servo drive is used in harsh environments, contact with corrosive gas, moisture, metal dust, water and processing liquid will cause the drive to fail. Therefore, during installation, the working environment of the drive must be guaranteed.

5. There are interfering devices near the servo drive

When there are interfering devices near the drive, it will have a great influence on the power line and control line of the servo drive, causing the drive to malfunction. Noise filters and other various anti-interference measures can be added to ensure the normal operation of the driver. Note that after adding a noise filter, the leakage current will increase. In order to avoid this problem, an isolation transformer can be used. Pay special attention to the fact that the control signal line of the driver is easily disturbed, and reasonable wiring and shielding measures are required.

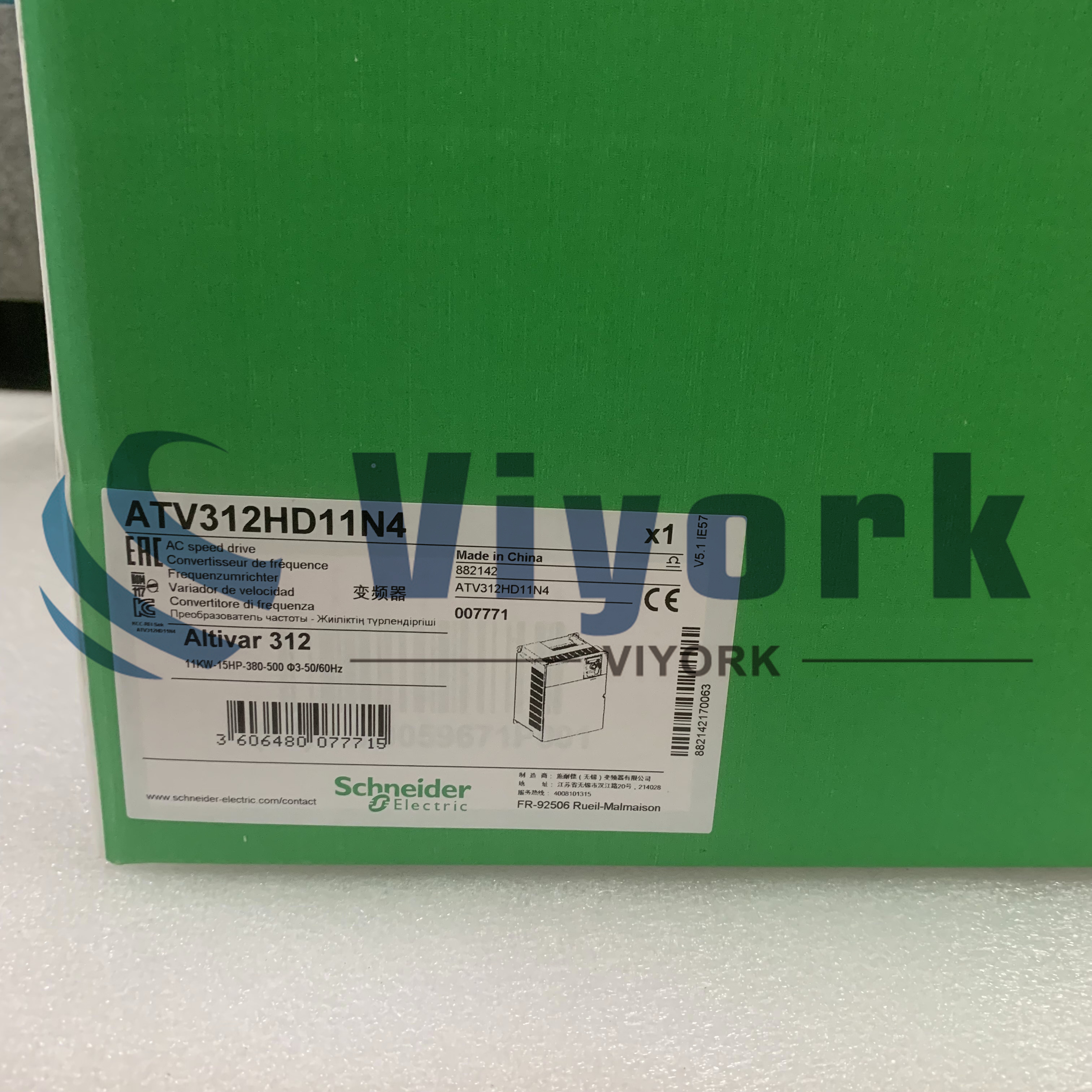

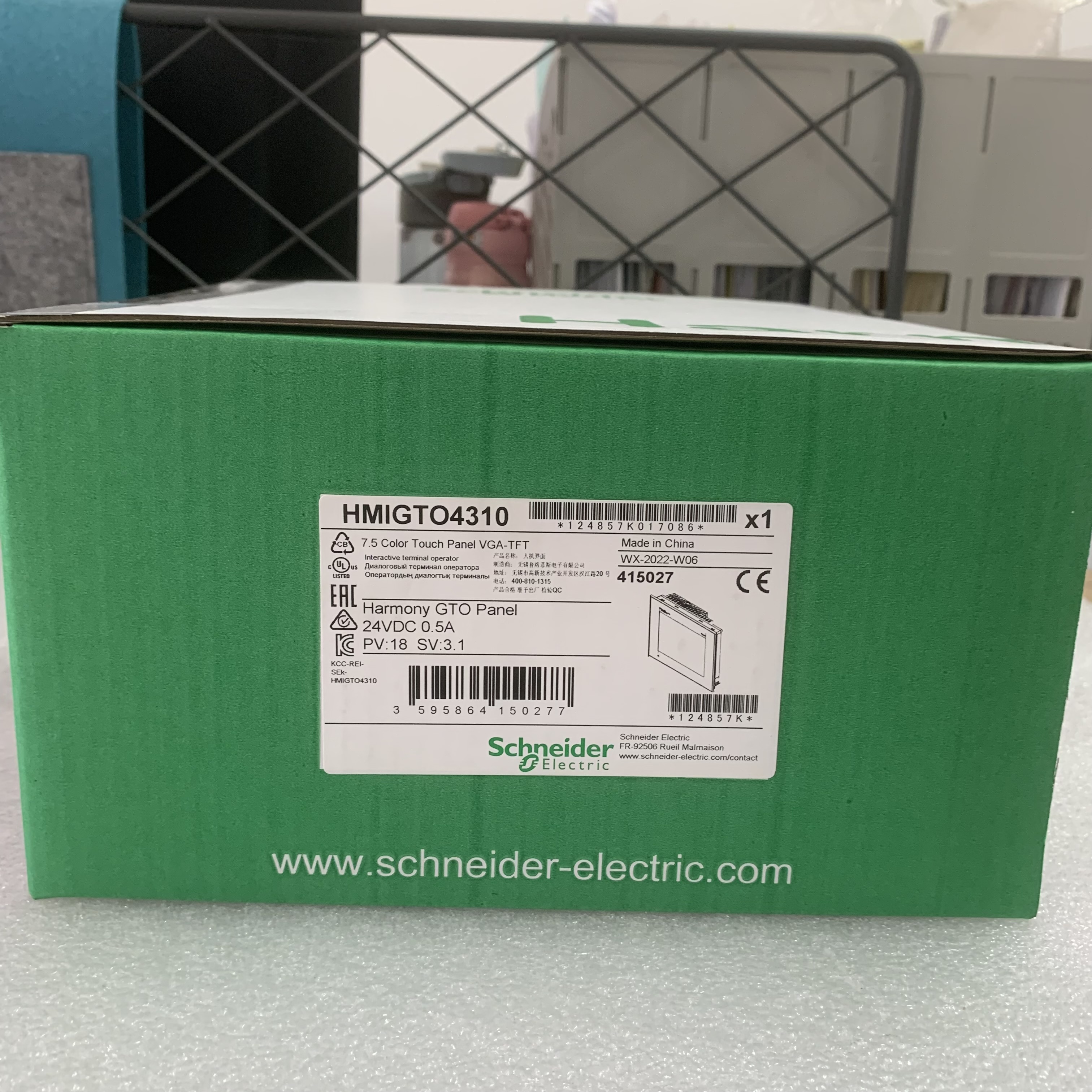

Viyouk is a industrial automation products supplier who provide a full industrial automation products list. You can search our industrial automation products by types or by manufacturers. Click to view more AC servo motor controllers and drives.

1. Installation direction: the normal installation direction of the servo drive: vertical and upright direction.

2. Installation and fixation: During installation, tighten the 4 m4 fixing screws at the rear of the servo drive.

3. Installation interval: The installation interval between servo drives and other equipment, in order to ensure the performance and life of the ab servo drives, please leave as much installation interval as possible.

4. Heat dissipation: The servo drive adopts natural cooling method, and a cooling fan must be installed in the electrical control cabinet to ensure that there is vertical wind to dissipate heat from the radiator of the servo drive.

5. Installation precautions: When installing the electrical control cabinet, prevent dust or iron filings from entering the servo drive.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China