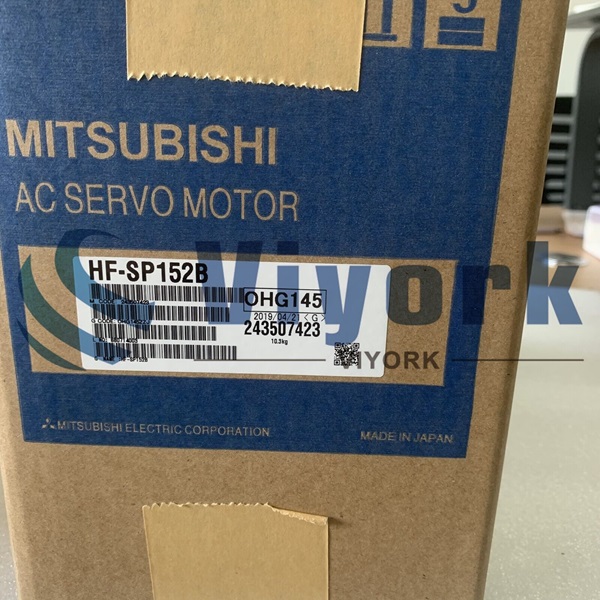

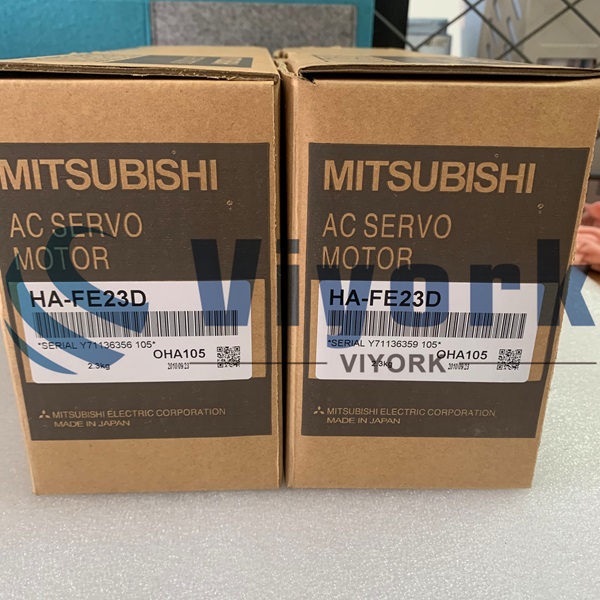

AC servo motor represents the pinnacle of precision motion control in modern automation systems. These sophisticated electromechanical devices combine precise positioning capabilities with high dynamic response, making them indispensable components in robotics, CNC machinery, and advanced manufacturing equipment. Unlike conventional motors, AC servo motor operates under closed-loop control, constantly receiving feedback to maintain exact positioning and speed. Viyork's selection of AC servo motor from leading manufacturers provides industrial users with reliable solutions for demanding automation applications where precision and repeatability are paramount.

The internal architecture of an AC servo motor reveals a carefully engineered system designed for optimal performance. At its core lies a high-performance rotor, typically constructed with permanent magnets that interact with the stator's electromagnetic fields. The stator features precision-wound copper coils arranged to create a rotating magnetic field when energized. Between these main components, high-resolution position encoders provide real-time feedback to the control system. The entire assembly is housed in a rugged frame that ensures proper heat dissipation while maintaining precise mechanical alignment. This thoughtful construction allows AC servo motor to deliver exceptional torque density and dynamic response characteristics.

AC servo motor operates on the principle of electromagnetic induction, where precisely timed currents create rotating magnetic fields that interact with the rotor's permanent magnets. The control system continuously monitors the rotor position through the encoder feedback and adjusts the stator current accordingly. This closed-loop control mechanism enables the motor to maintain exact speed and position, even under variable load conditions. The stator windings are energized in a controlled sequence to produce smooth rotation, while advanced control algorithms optimize torque production and minimize energy consumption. These operating principles explain why an AC servo motor demonstrates superior dynamic performance compared to a conventional induction motor.

While both AC and DC servo motors serve motion control applications, their operational characteristics reveal significant differences. AC servo motor typically offers higher efficiency due to their permanent magnet rotors and electronic commutation, eliminating the brush wear issues inherent in DC designs. The absence of mechanical commutators in AC designs results in lower maintenance requirements and longer service life. In terms of performance, AC servo motor generally provides better speed regulation and smoother operation at low speeds. The table below highlights these key differences:

Characteristic | AC Servo Motor | DC Servo Motor |

Commutation Method | Electronic | Mechanical (brushes) |

Maintenance Requirements | Low | Moderate to High |

Efficiency | High | Moderate |

Speed Range | Wide | Limited at high speeds |

Torque at Low Speed | Excellent | Good |

Lifespan | Long | Shorter due to brush wear |

AC servo motor finds extensive use across numerous industrial automation scenarios where precise motion control is essential. In robotic systems, they enable accurate joint positioning and smooth movement execution. CNC machine tools rely on AC servo motor for spindle control and precise axis movements that guarantee machining accuracy. Packaging lines utilize these motors for high-speed, repetitive operations requiring exact positioning. The combination of high torque density and precise control makes AC servo motor particularly valuable in applications demanding both power and finesse. Viyork's comprehensive range of AC servo motor solutions supports these diverse industrial needs with reliable performance.

Proper maintenance and system optimization significantly enhance the performance and longevity of AC servo motor. Regular inspection of mechanical connections and proper lubrication of associated components help prevent premature wear. Environmental factors such as temperature and humidity should be monitored, as excessive heat can degrade motor performance over time. Electrical connections require periodic verification to ensure proper signal transmission and power delivery. System tuning, including proper PID loop adjustment and feedforward parameter setting, plays a crucial role in maximizing the motor's dynamic response while minimizing energy consumption. These maintenance practices, when combined with quality AC servo motor from reputable suppliers like Viyork, result in reliable, long-lasting motion control solutions.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China