Maintaining and caring for a servo motor driver is essential for ensuring the longevity, reliability, and efficiency of your automation systems. Servo motor drivers are critical components in industries such as robotics, CNC machinery, and packaging, as they control the operation of the motors that drive these machines. In this article, we will discuss how to properly maintain your servo motor driver, focusing on key maintenance steps, the role of regular inspections, and how proper care can prevent downtime and costly repairs.

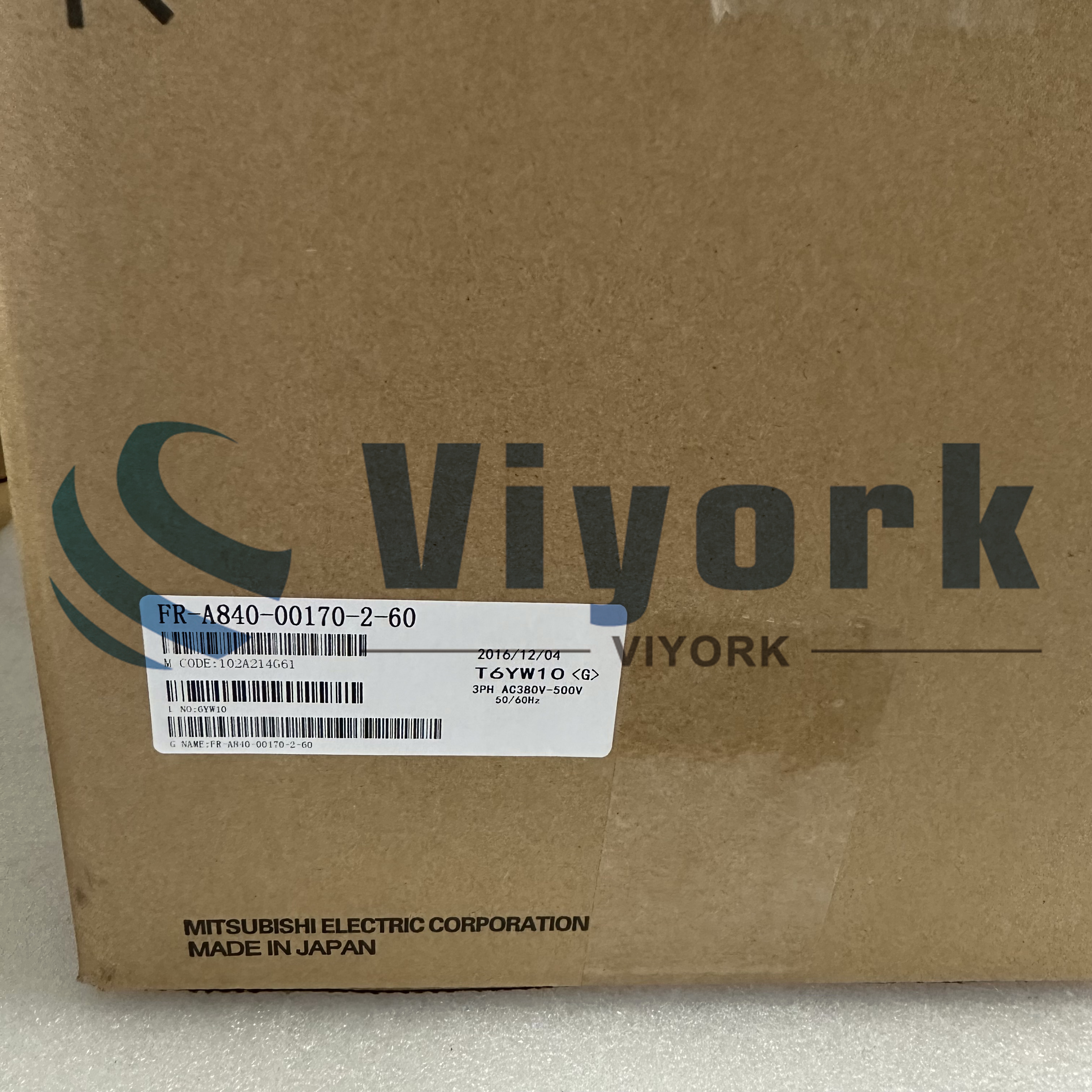

Servo motor drivers, like the ones from Viyork, are designed to deliver precision control for your machinery. However, regular maintenance is necessary to keep them performing at their best. Neglecting maintenance can lead to various issues, such as overheating, power failures, or inaccurate motor control. Regular inspection and cleaning can identify potential problems before they escalate, ensuring the servo motor driver operates smoothly and efficiently over time. Whether you're using a servo motor driver in a manufacturing plant, an assembly line, or a robotic system, taking the time for proper maintenance will prolong the life of your equipment and prevent unexpected breakdowns.

Proper care and maintenance of your servo motor driver can involve several steps. First, it's crucial to ensure that the driver is installed correctly and operates within the recommended environment. Overheating is one of the most common causes of failure in servo motor drivers. To prevent this, ensure that the unit has adequate ventilation and is kept in a clean, dust-free environment. Regularly check for any dirt or debris accumulation that may impede airflow, as this can cause the motor driver to overheat and malfunction.

Second, inspecting the power supply and wiring connections is vital. Loose or corroded connections can lead to power instability, affecting the driver’s performance. Additionally, monitoring the system's voltage to ensure it remains within the recommended range helps prevent power surges that could damage the servo motor driver. For servo motor driver maintenance, it's important to perform periodic inspections and, if necessary, replace any worn-out or damaged components.

Viyork's servo motor drivers, such as those available on their website, are built with high-quality materials and designed for easy maintenance. Their intuitive design simplifies the installation and maintenance process, allowing technicians to quickly identify and fix any issues. With advanced features such as built-in diagnostic tools, Viyork's servo motor drivers enable users to monitor the system's health in real-time, making maintenance tasks much more manageable. These drivers are engineered to be durable and reliable, ensuring that they can withstand harsh industrial environments while minimizing the need for frequent repairs or replacements.

Furthermore, Viyork's servo motor drivers are optimized for energy efficiency, which not only improves performance but also reduces wear and tear over time, ultimately leading to fewer maintenance requirements. The advanced design and technology used in Viyork products ensure that users can enjoy optimal performance with less intervention needed for repairs.

The impact of regular maintenance on servo motor drivers cannot be overstated. Neglecting maintenance can result in reduced efficiency, higher costs, and even system failures. Below is a comparison table highlighting the differences between servo motor drivers that are regularly maintained and those that are not:

Maintenance Aspect | With Regular Maintenance | Without Regular Maintenance |

System Efficiency | High efficiency, optimal performance | Decreased efficiency, potential for overloads |

Performance Reliability | Consistent, reliable performance over time | Unstable performance, increased failure risk |

Lifespan | Longer lifespan, reduced wear and tear | Shortened lifespan due to frequent malfunctions |

Energy Consumption | Lower energy usage, optimized power consumption | Higher energy consumption, inefficient operation |

Downtime | Minimal downtime, quick recovery from issues | Frequent downtime due to unexpected failures |

Maintenance Cost | Reduced costs for repairs and replacements | Increased repair costs and more frequent breakdowns |

Error Detection | Quick error detection and troubleshooting | Errors may go unnoticed until they cause serious damage |

From the table, it's clear that regular maintenance of servo motor drivers results in greater efficiency, fewer repairs, longer lifespan, and lower energy costs. On the other hand, neglecting maintenance can lead to performance instability, higher energy consumption, and increased downtime, all of which can be costly in the long run.

Maintaining and caring for your servo motor driver is crucial for ensuring the long-term efficiency and performance of your automation systems. By following the key maintenance tips outlined in this article, such as proper installation, regular inspections, and environmental care, you can prevent unnecessary downtime and costly repairs. Viyork's servo motor drivers offer excellent ease of maintenance, energy efficiency, and reliability, making them a great choice for businesses seeking to improve the lifespan and performance of their automation equipment.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China