Industrial automation continues to evolve, driving demand for high-performance motion control solutions. AC motor servo systems stand at the forefront of this revolution, delivering unmatched precision, efficiency, and reliability in robotics, CNC machinery, and automated production lines. Viyork, a leading supplier of industrial automation components under Shenzhen Weiyousheng Technology Co., LTD, offers a comprehensive range of AC motor servo from global manufacturers such as Mitsubishi, Yaskawa, Siemens, and ABB. With a growing presence in China and worldwide, Viyork is committed to providing top-tier automation solutions that enhance productivity and operational efficiency.

AC motor servo are designed for high-speed, high-torque applications where precise control is critical. These motors operate using three-phase AC power, which generates a rotating magnetic field in the stator, interacting with the rotor's permanent magnets to create motion.

Unlike standard induction motors, AC motor servo incorporate built-in encoders that provide real-time feedback to the servo drive, ensuring exact positioning, speed regulation, and torque control. This closed-loop system makes them ideal for CNC machining, robotics, and packaging automation, where micron-level accuracy is essential.

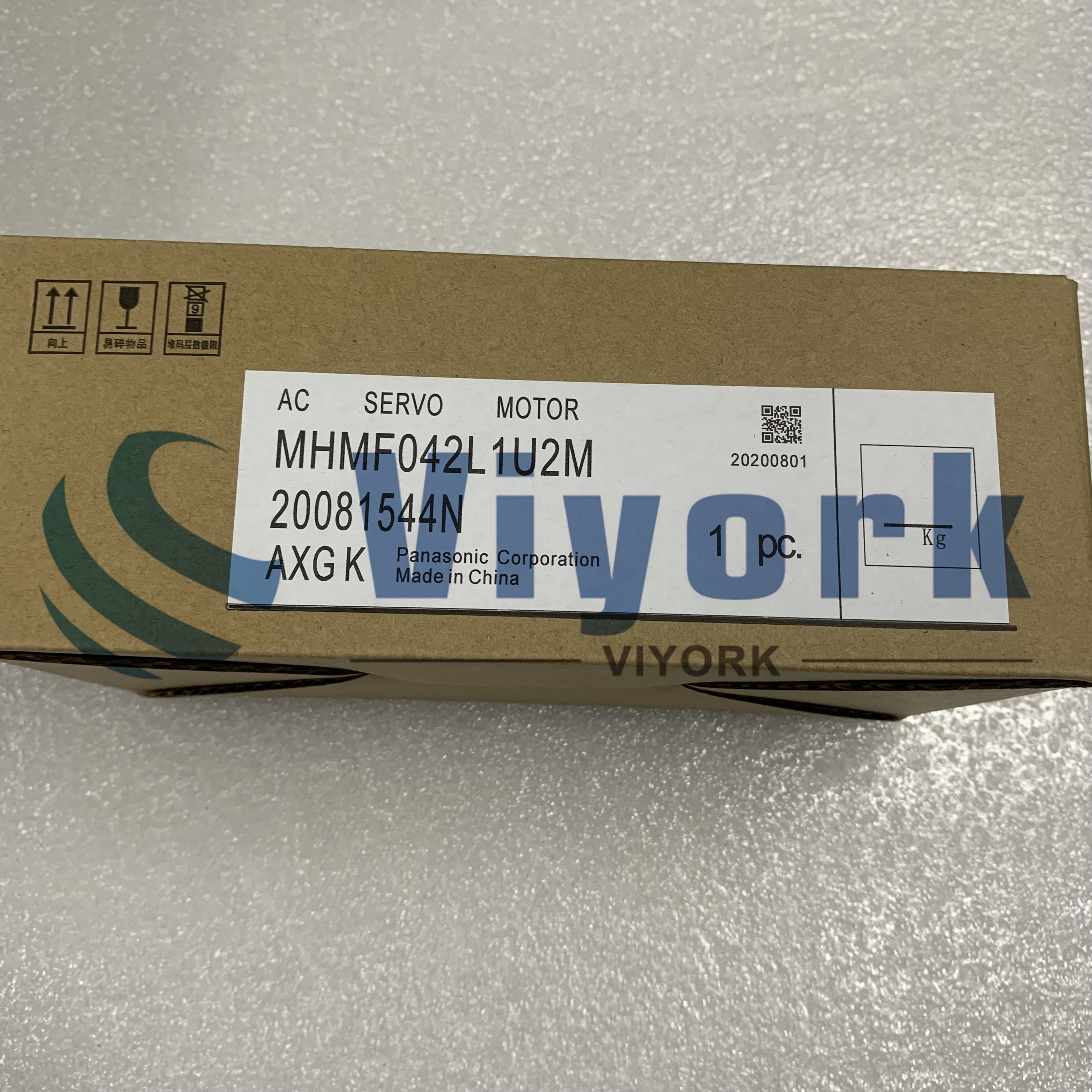

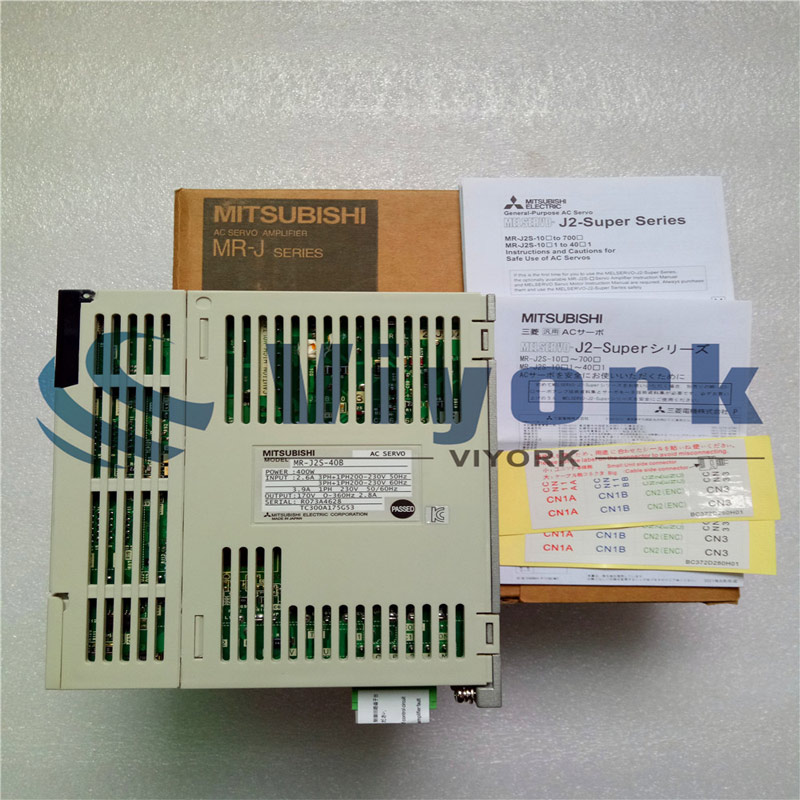

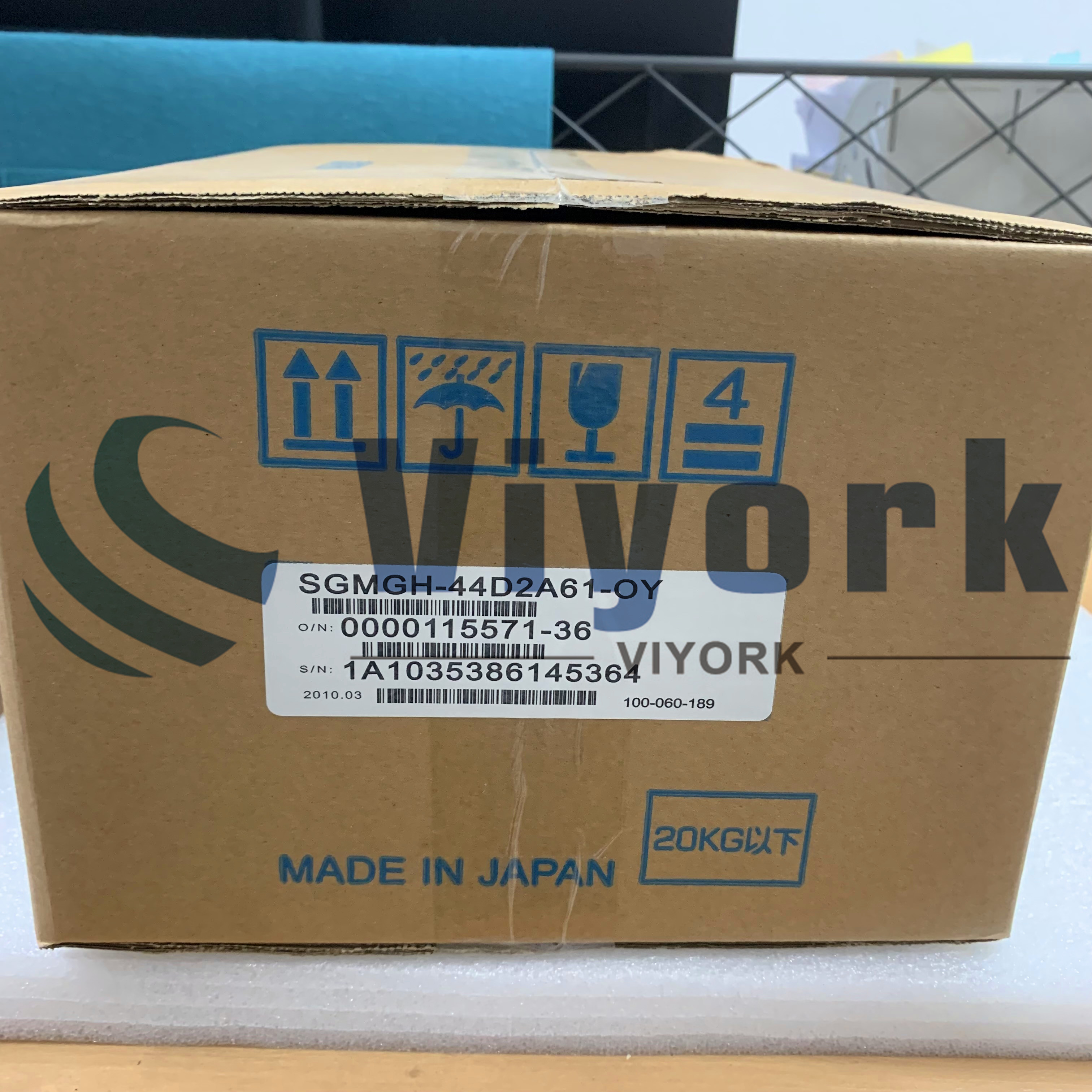

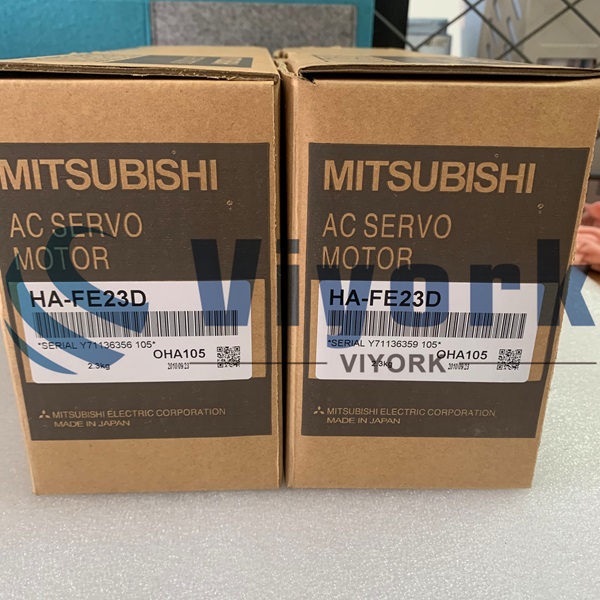

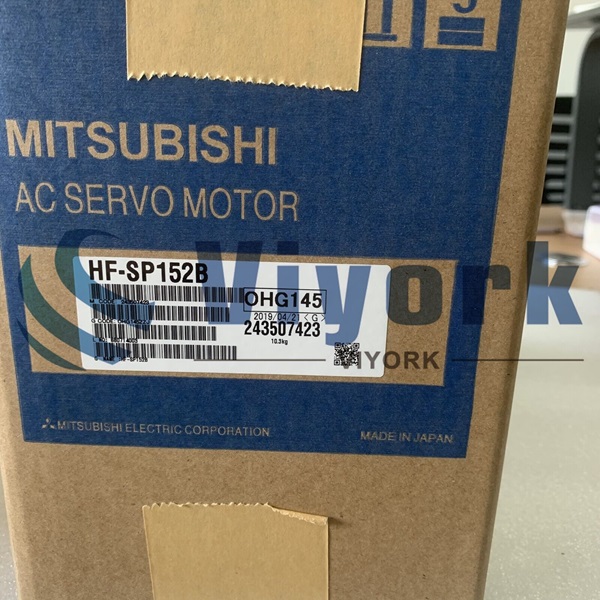

Viyork's selection of AC motor servo includes models from top brands like Mitsubishi and Panasonic, ensuring compatibility with various automation systems such as Honeywell DCS and Allen-Bradley PLCs.

When choosing between AC and DC servo motors, several factors must be considered—including efficiency, maintenance requirements, and performance in different applications. The table below highlights the key differences:

Feature | AC Servo Motor | DC Servo Motor |

Power Source | AC (3-phase/single-phase) | DC (brushed/brushless) |

Maintenance | Low (no brushes or commutators) | Higher (brush replacement needed) |

Efficiency | High (>90%) | Moderate (80-90%) |

Speed & Torque | Consistent at high speeds | High torque at low speeds |

Lifespan | Longer due to brushless design | Shorter due to brush wear |

For most industrial automation applications, AC motor servo are the preferred choice due to their durability, efficiency, and superior performance in high-speed operations. Viyork's AC motor servo solutions cater to industries such as semiconductor manufacturing, automotive assembly, and industrial robotics, ensuring optimal energy usage and reliability.

AC motor servo require a compatible servo drive (amplifier) and controller to function efficiently. The servo drive converts input signals (either analogue or digital) into precise voltage and current outputs, adjusting motor speed, torque, and positioning.

Most AC motor servo use advanced communication protocols such as EtherCAT, PROFIBUS, or MODBUS, allowing seamless integration with PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems). Additionally, manufacturers like Yaskawa and ABB provide programmable servo drives that enable real-time adjustments to optimize performance under varying loads.

Viyork supplies AC motor servo and drives from top-tier brands, ensuring smooth integration with existing automation setups while enhancing motion control accuracy.

AC servo motor technology has revolutionized precision automation with its brushless design, high power density, and superior dynamic response.

Key innovations in AC servo technology include:

Regenerative braking, which recovers energy and reduces power consumption.

Smart tuning functions that adjust motor parameters automatically for optimal load response.

Integrated safety features, ensuring compliance with industrial automation standards.

With Viyork's expertise in supplying AC motor servo from ABB, Siemens, and GE Fanuc, industries worldwide benefit from cutting-edge motion control solutions.

Choosing the best AC servo motor involves evaluating several key factors:

Load requirements (torque, inertia, and speed).

Feedback resolution (encoder type and precision).

Communication interface (EtherCAT, CANopen, etc.).

Environmental conditions (temperature, dust, and moisture resistance).

For applications requiring high-speed precision (such as robotics and CNC machines), Yaskawa and Mitsubishi AC motor servo excel due to their low vibration and smooth operation. In contrast, heavy-duty industries (e.g., metalworking) may opt for Siemens or ABB motors for their rugged durability.

Viyork's comprehensive range of AC motor servo ensures businesses find the perfect fit for their automation needs, backed by technical support and global supply chain reliability.

As industrial automation advances, AC motor servo systems continue to play a crucial role in enabling high-speed, high-precision motion control. With Viyork's industry-leading partnerships and automation expertise, businesses gain access to top-tier AC motor servo that maximize efficiency and productivity.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China