Before operating a DC servo motor driver, one of the most critical steps is correct wiring. Improper connections can lead to motor malfunction, driver damage, or even safety hazards. Always follow the manufacturer's wiring diagram and verify polarity, grounding, and shielded cable usage. It's essential to keep signal wires separate from power lines to minimize electromagnetic interference (EMI), which can disrupt control signals and reduce system performance.

Additionally, ensure that the DC servo motor driver is electrically isolated from external control systems unless otherwise specified. Using opto-isolators or differential signal transmission can help protect sensitive electronics and maintain signal integrity.

Selecting a compatible DC servo motor driver for your motor is vital for safe and efficient operation. The voltage, current rating, encoder type, and control interface must all align with the motor specifications. Using an underpowered driver may result in inadequate torque or overheating, while an oversized driver could cause control instability or damage to system components.

Also, application requirements—such as speed, torque, load inertia, and duty cycle—should be considered when configuring the DC servo motor driver. Ensure the driver's parameters (such as acceleration limits and gain settings) are tuned appropriately for the application to prevent overshooting, resonance, or mechanical stress.

Like all electronic equipment, a DC servo motor driver generates heat during operation. Overheating can reduce lifespan, lead to thermal shutdown, or degrade performance. Always install the driver in a well-ventilated control panel or enclosure, and avoid placing it near high-heat sources. If the DC servo motor driver includes a built-in heatsink or fan, confirm that airflow is not obstructed.

Proper mounting is equally important. Drivers should be installed securely on a stable, vibration-free surface using recommended mounting brackets or rails. Avoid mounting the DC servo motor driver in locations subject to oil mist, moisture, or conductive dust, as these can cause short circuits or corrosion.

After physical installation, software configuration is the next crucial step. Most DC servo motor drivers allow extensive parameter tuning to match the dynamics of the motor and load. Parameters such as PID gain, acceleration/deceleration limits, current limits, and soft start/stop settings must be adjusted carefully.

Always start with default or conservative settings and incrementally tune the system based on real-time feedback. Many DC servo motor drivers include auto-tuning features, but manual fine-tuning is often necessary for precision-critical applications. Monitor the system for signs of instability, such as hunting, oscillation, or overheating, and adjust accordingly.

In addition, save configuration profiles and log data during the tuning process. This allows for easier troubleshooting and replicability in future installations using the same DC servo motor driver.

Continuous performance monitoring is essential to ensure the long-term reliability of your DC servo motor driver. Integrate status diagnostics such as voltage, current, fault codes, and motor position feedback into your control system. Modern DC servo motor driver provides real-time monitoring through a PC interface or industrial network protocol.

Pay close attention to fault indications like overcurrent, overvoltage, encoder errors, or temperature warnings. These alerts not only protect the driver but can also indicate deeper issues in your system's mechanical or electrical components.

From a safety standpoint, always disconnect power before servicing the DC servo motor driver, and use lockout/tagout procedures in industrial environments. Train personnel to understand the driver's fault codes, LED indicators, and emergency stop logic to minimize downtime and ensure operator safety.

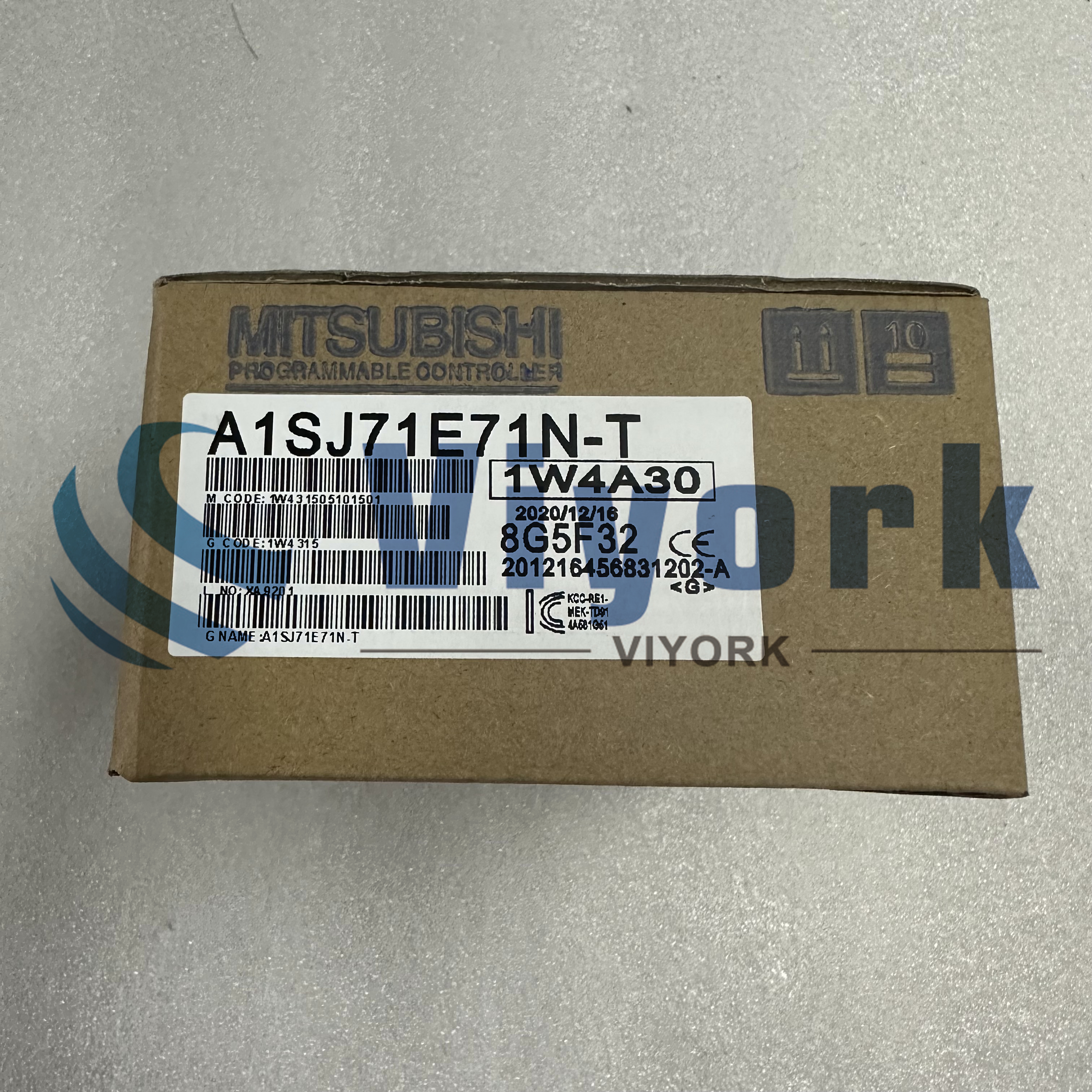

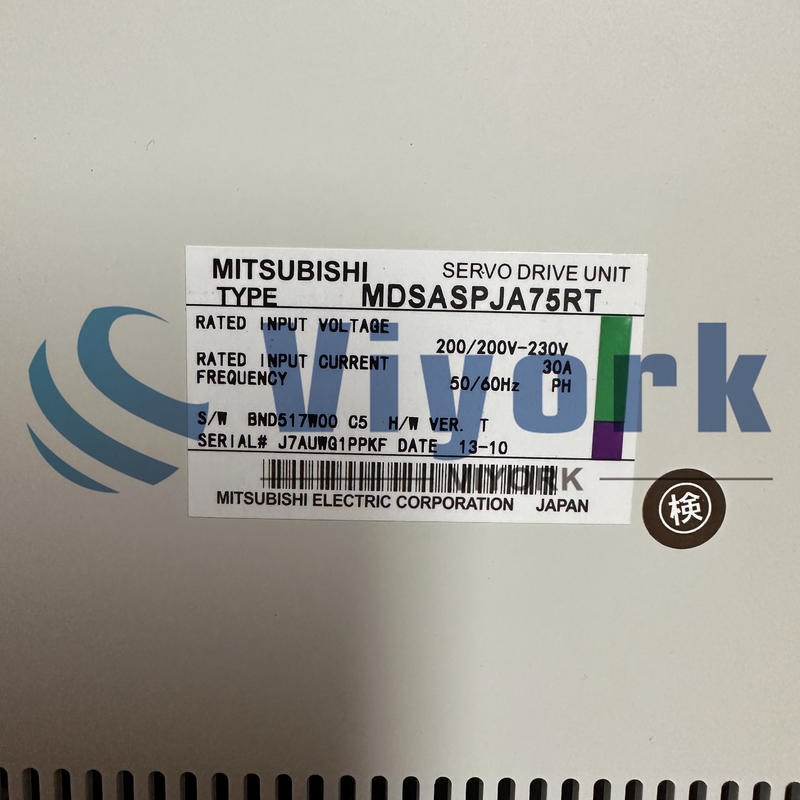

Viyork offers expertly engineered DC servo motor driver designed to support high-performance motion systems with safety, adaptability, and durability at the core.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China