The encoder is a device that can encode signals or data and converts them into signals that can be used for communication, transmission, and storage.

The servomotor encoder is applied in the OEM market, such as machine tools, elevators, servo motor supporting, textile machinery, packaging machinery, printing machinery, lifting machinery and so on industries. We adopt types of automation technology to produce this servo encoder.

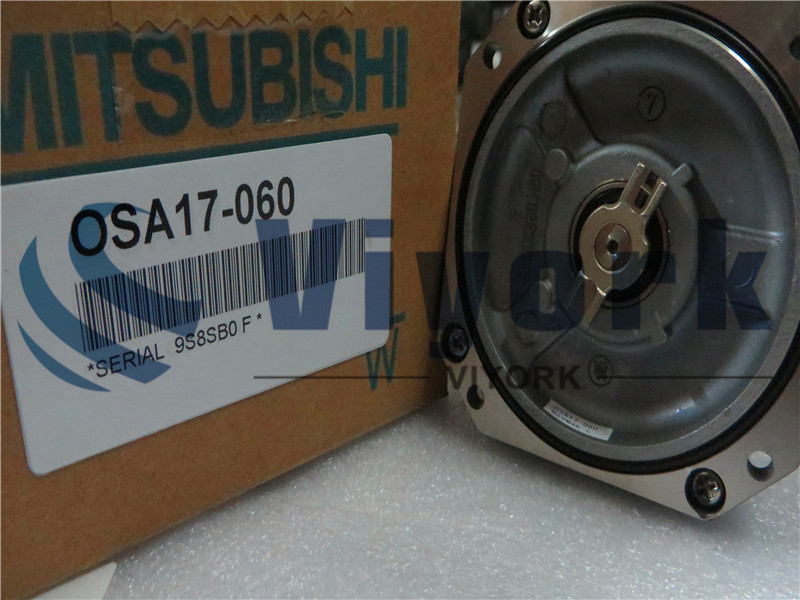

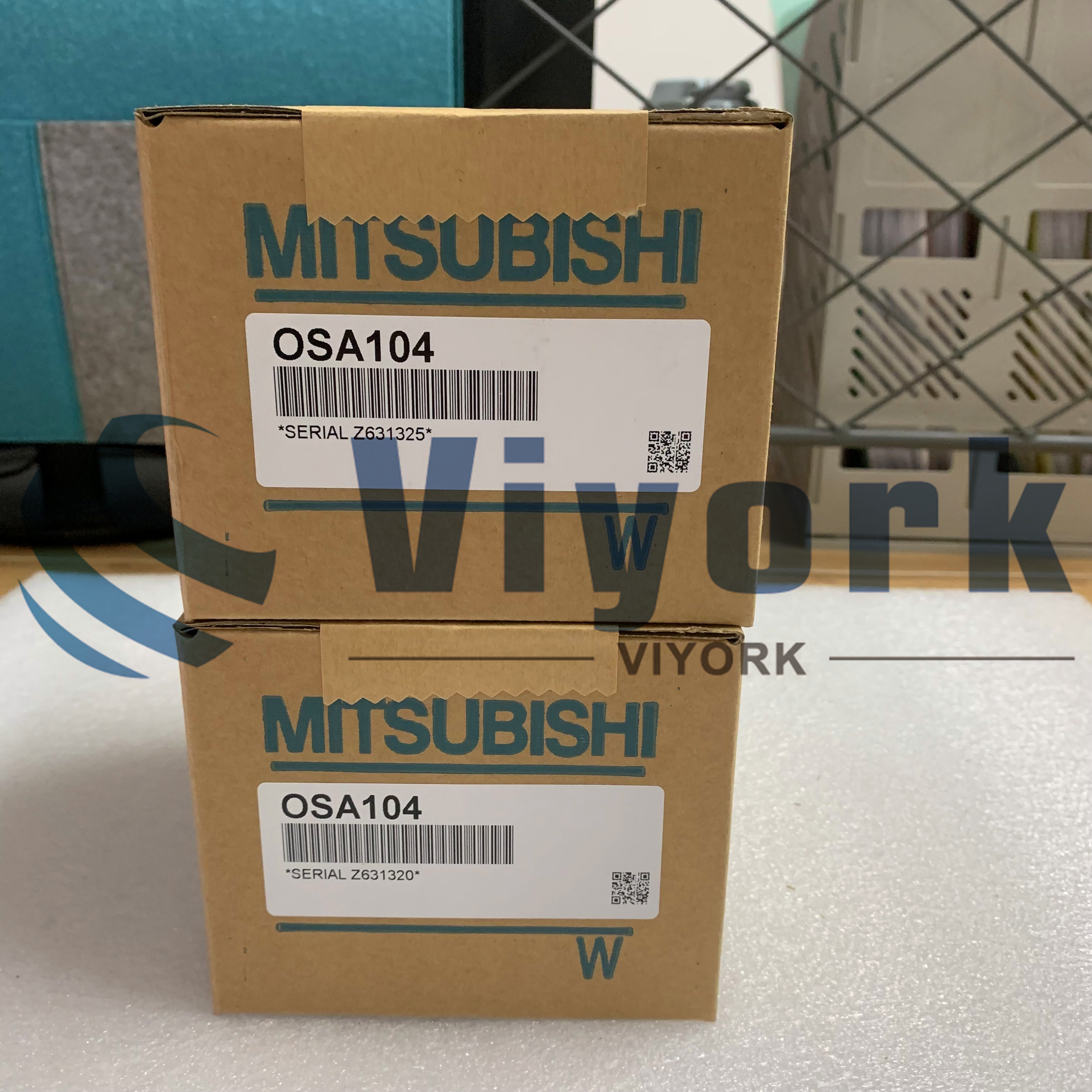

The competition of encoder manufacturers mainly focuses on offering the servo motor to these machinery industries, like Yokogawa industrial automation company, and the servo motor encoder price is competitive as well. As a professional servo motor encoder distributor, Viyork can provide you with Yaskawa servo motor encoder, Mitsubishi servo motor encoder, etc.

With the improvement of mechanical equipment automation, the application field of the encoder becomes wider and wider. We should focus on the production of components of industrial automation, including not only the servomotor encoder but also the plc programmable controller, servo drive and other products.

In terms of the servo encoder, the customers are no longer satisfied with the Physical rotation signal and converted to an electrical signal which also requires the encoder is more integrated and durable. Many servo motor encoder types are merging. The customers also hope that the absolute encoder has more abundant connectors and can make more equipment intellectualization.

An encoder for servo motor is a device that encodes a signal (such as a bitstream) or data and converts it into a signal form that can be communicated, transmitted, and stored. The encoder converts the angular displacement or linear displacement into an electrical signal. The former is called the code disc and the latter is called the code ruler.

A simple encoder used in servo motor is a rotating sensor that converts a rotational displacement into a series of digital pulses. These pulses can be used to control angular displacements. If the servo motor encoder is combined with a gear bar or screw, it can measure linear displacements with numerous benefits as follows.

Exceedingly reliable and accurate

Higher resolution

Cost-saving in feedback

Integrated electronics

Compact in size

Fuses optical and digital technology

As a reliable and professional servo motor encoder manufacturer, we are adhering to provide you encoders of different brands such as Mitsubishi servo motor encoder, Yaskawa servo motor encoder, Fanuc servo motor encoder, etc. with a reasonable price.

A servo motor encoder is used only to measure the motor's operation. The two encoders can achieve high positional accuracy. Also, the combination of servo encoder eliminates stability problems linked with mechanical compliance.

A servo motor encoder generates the electrical signal and it is processed by numerical control CNC, programmable logic controller PLC and control system. Then the sensors are used in machine tools, material processing and motor feedback systems.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China