In today's rapidly advancing industrial landscape, AC motor servo systems have become indispensable components in precision motion control applications. Viyork, as a trusted supplier in the automation industry, offers a comprehensive range of AC motor servo solutions from leading global brands. These sophisticated systems combine high-performance AC motors with advanced servo motor drivers to deliver exceptional speed, torque, and positioning accuracy. At their core, AC motor servo systems transform electrical energy into precise mechanical motion through the seamless integration of motors, servo motor drivers, and feedback devices.

The working principle of AC motor servo systems revolves around three-phase power and closed-loop control. When combined with high-quality servo motor drivers, these systems can achieve positioning accuracies within microns, making them ideal for demanding applications in robotics, CNC machinery, and automated production lines. The servo motor driver acts as the intelligent interface between the control system and the motor itself, converting command signals into precisely controlled electrical currents that drive the motor with exceptional accuracy.

AC motor servo offer numerous benefits that make them superior to conventional motor solutions in industrial automation. With their brushless design and permanent magnet rotors, these motors deliver high torque at low speeds while maintaining efficiency across their entire speed range. The integration with precision servo motor drivers ensures smooth operation with minimal vibration and noise, even during complex motion profiles. This combination results in extended equipment lifespan and reduced maintenance requirements compared to traditional motor systems.

Energy efficiency represents another significant advantage of modern AC motor servo systems. When paired with advanced servo motor drivers featuring regenerative braking capabilities, these systems can recover and reuse energy that would otherwise be wasted during deceleration. This energy-saving feature, combined with the high efficiency of permanent magnet motors, helps industrial operations reduce their power consumption and operating costs. Furthermore, the compact design of contemporary AC motor servo allows for space-saving installations without compromising performance.

The choice between AC and DC servo motors remains a critical decision in industrial automation, with each technology offering distinct advantages. AC motor servo, when combined with modern servo motor drivers, provide superior performance in most industrial applications due to their brushless design, higher speed capabilities, and better heat dissipation. Unlike DC motors that rely on brushes for commutation, AC motor servo eliminate brush wear entirely, resulting in longer service life and reduced maintenance costs.

DC servo motors traditionally offered better torque characteristics at low speeds, but advancements in AC motor servo technology and servo motor driver capabilities have largely closed this gap. Modern AC servo systems now deliver excellent low-speed torque performance while maintaining superior efficiency at higher speeds. The servo motor drivers for AC systems also provide more sophisticated control algorithms and networking capabilities, making them better suited for integration with modern industrial control systems and Industry 4.0 applications.

AC motor servo systems find applications across a wide range of industries where precision motion control is paramount. In robotic automation, these systems power articulated arms with the accuracy and repeatability needed for delicate assembly operations. The combination of high-performance AC motor servo and advanced servo motor drivers enables robots to execute complex trajectories with minimal error, even at high speeds.

CNC machining represents another critical application area for AC motor servo technology. Here, the precise positioning and rapid response enabled by quality servo motor drivers allow machine tools to maintain tight tolerances while maximizing productivity. Packaging machinery also benefits from AC servo systems, where the ability to make quick, accurate movements improves line efficiency and reduces material waste. Throughout these applications, the reliability and performance of the servo motor driver play a crucial role in maintaining system uptime and product quality.

Choosing the appropriate AC motor servo system requires careful consideration of several factors to ensure optimal performance in specific applications. The selection of compatible servo motor drivers is equally important, as these devices significantly impact the overall system behavior. Engineers must evaluate torque and speed requirements, load characteristics, and environmental conditions when specifying these systems.

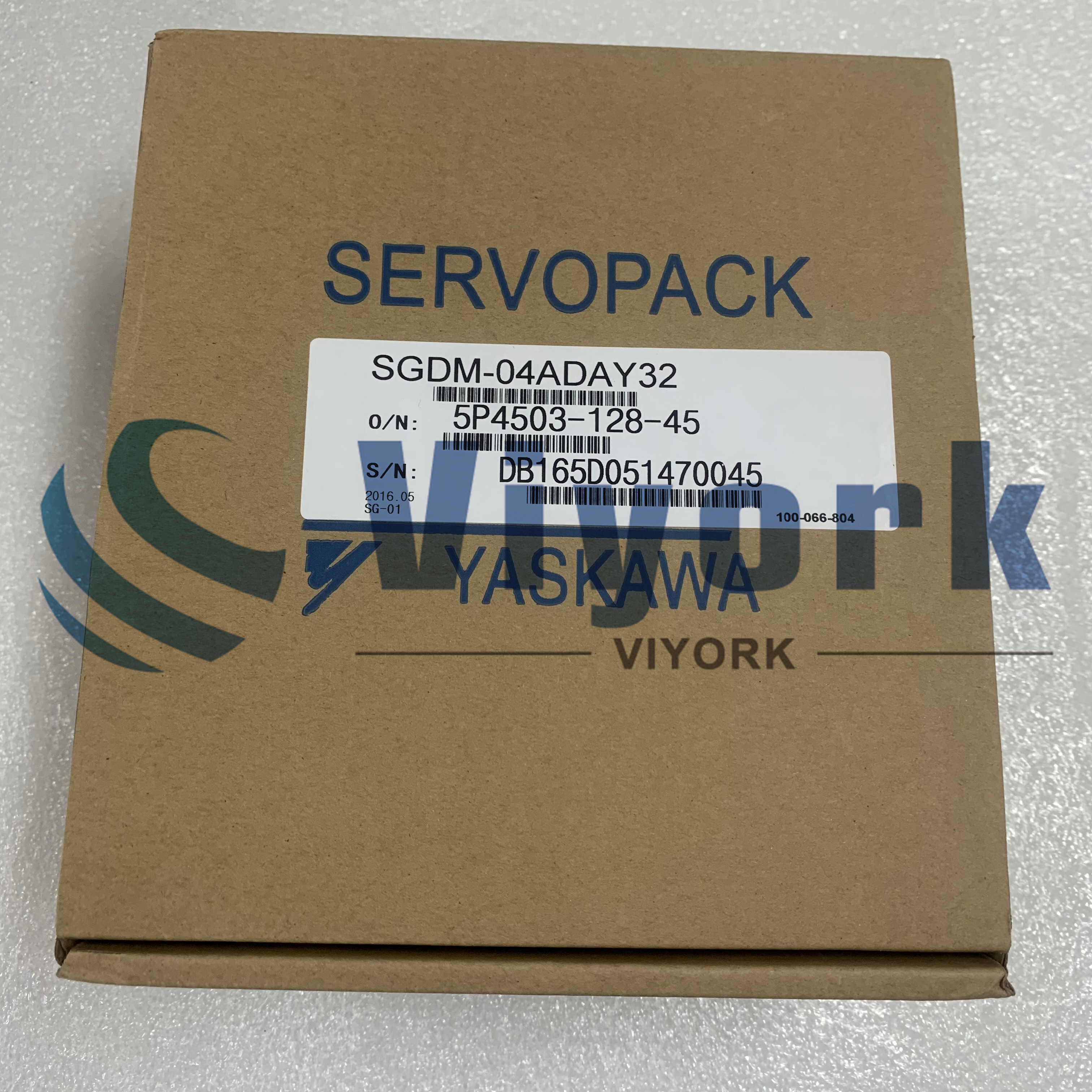

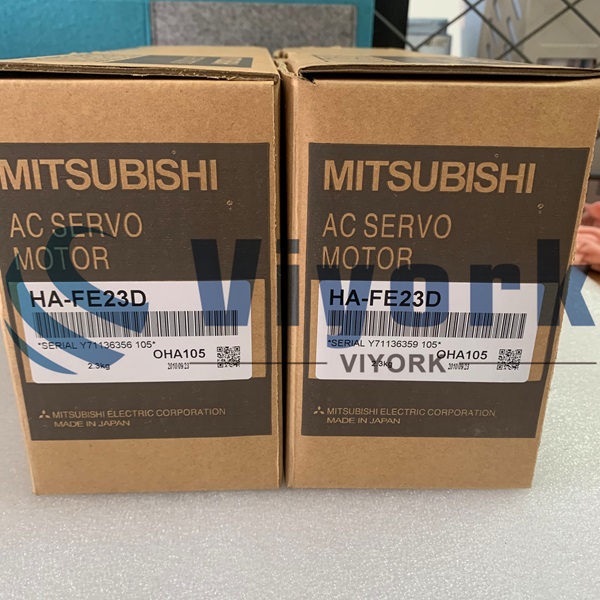

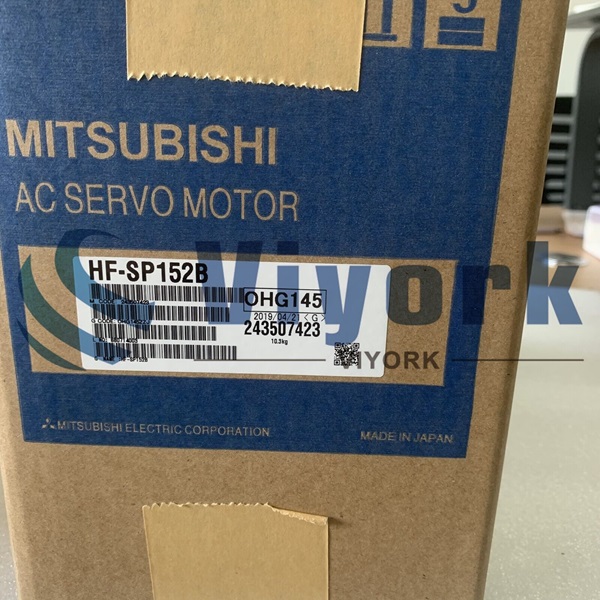

Viyork's extensive product portfolio includes AC motor servo solutions suitable for various industrial needs, from small-scale automation to heavy-duty manufacturing. The company's expertise in matching motors with appropriate servo motor drivers helps customers achieve the best balance of performance, efficiency, and cost-effectiveness. With proper selection and integration, AC motor servo systems can significantly enhance the capabilities of automated equipment while reducing long-term operating costs.

For organizations looking to implement or upgrade their motion control systems, Viyork offers a range of AC motor servo solutions backed by technical support and industry knowledge. Their product offerings, available at Viyork, include options from leading manufacturers to meet diverse automation requirements.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China