One of the most defining features of a DC servo motor driver is its ability to deliver high-precision control through a closed-loop feedback system. Unlike open-loop stepper systems, DC servo motor driver continuously monitors position, velocity, and torque through encoders or other feedback devices. This real-time adjustment mechanism ensures accurate performance even under varying load conditions or during rapid acceleration and deceleration cycles.

The closed-loop nature of a DC servo motor driver not only enhances accuracy but also reduces the risk of position loss, overheating, and mechanical strain. This makes it ideal for mission-critical applications such as CNC machining, robotic automation, and advanced optical equipment.

A DC servo motor driver is engineered for dynamic performance, offering fast response times with minimal delay. This rapid responsiveness is crucial in applications where motion sequences must be tightly coordinated, such as in pick-and-place robots, high-speed conveyors, and precision inspection systems.

In addition to speed, DC servo motor driver is designed to ensure smooth, jitter-free motion, minimizing vibration and mechanical resonance. The ability to finely tune acceleration and deceleration profiles contributes to quieter and more stable operation. This level of smoothness is particularly beneficial in environments requiring minimal noise and vibration, such as medical equipment and laboratory automation.

Modern DC servo motor driver supports a range of control modes including position, speed, and torque control, allowing system designers the flexibility to optimize for specific operational needs. Whether the goal is to maintain constant speed or achieve precise positional alignment, the DC servo motor driver can be configured to deliver the desired behavior with accuracy and repeatability.

Furthermore, advanced DC servo motor driver comes equipped with a variety of communication interfaces such as RS-485, CANopen, EtherCAT, or Modbus, enabling seamless integration into complex industrial networks. This connectivity allows for synchronized multi-axis motion control and easy diagnostics, ensuring that the DC servo motor driver remains adaptable to future upgrades or system expansions.

Another notable feature of the DC servo motor driver is its energy-efficient design. These drivers are built to deliver high torque-to-current ratios, reducing energy consumption while maximizing output. Some models also support regenerative braking, where excess energy from deceleration is fed back into the power supply, further improving overall efficiency.

The compact footprint of the DC servo motor driver allows for easy installation in space-constrained applications. From embedded automation to portable devices, the small size and modular design of the DC servo motor driver provide engineers with greater design flexibility without compromising performance.

Safety and durability are also central to the design of a DC servo motor driver. Built-in protections such as overvoltage, overcurrent, overheating, and stall detection help prevent damage to both the driver and the motor. These protective features ensure that the system remains stable and safe even in unpredictable operating conditions.

Some advanced DC servo motor drivers also include adaptive tuning algorithms that automatically adjust control parameters based on motor characteristics or application requirements. This smart feature significantly reduces setup time and optimizes performance across a variety of operating conditions. Additionally, user-friendly software tools often accompany the DC servo motor driver, providing intuitive interfaces for configuration, monitoring, and troubleshooting.

In conclusion, the DC servo motor driver stands out as a vital component in precision motion control systems. With features such as high-resolution feedback, rapid response, flexible communication, energy efficiency, and built-in protection, it meets the demands of both industrial and high-tech environments. Its adaptability and performance make it the preferred choice for engineers and integrators looking to push the boundaries of automation and control systems.

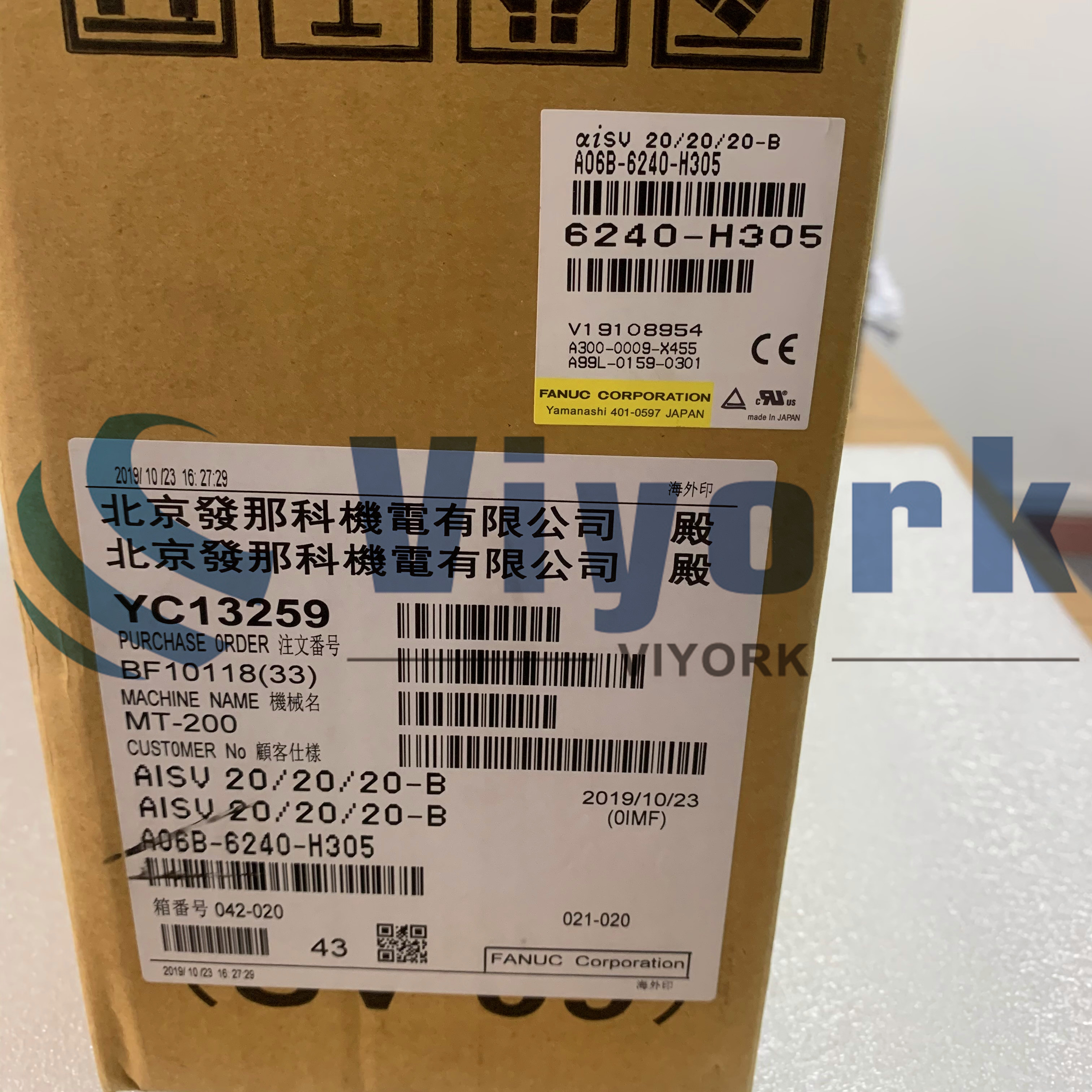

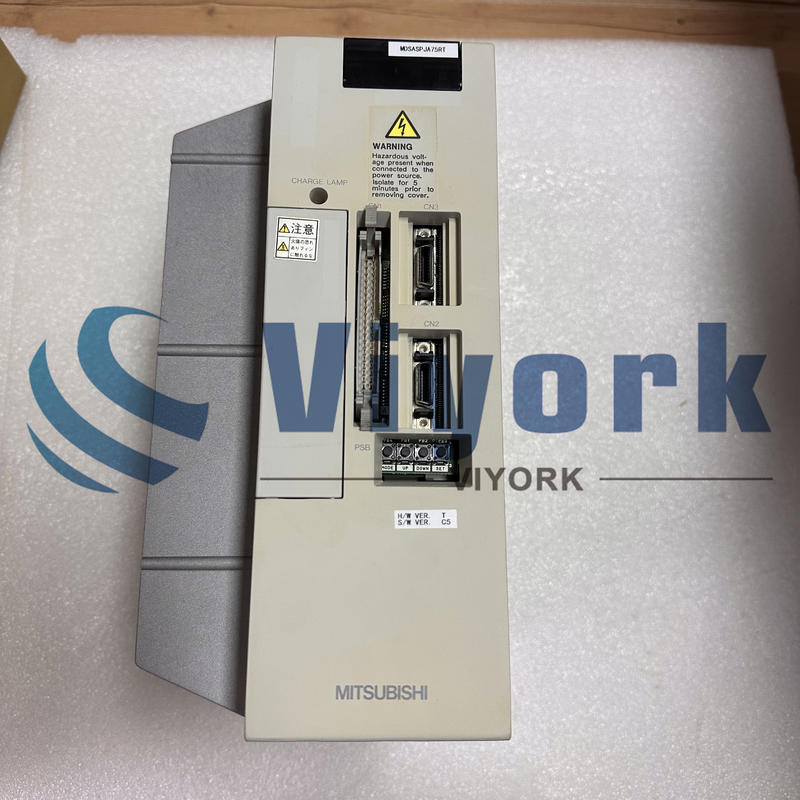

Viyork offers DC servo motor driver that embodies these advanced features, delivering reliable, high-performance solutions for today's most demanding motion control applications.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China