There are three types of control on ab servo drives: speed control, torque control, and position control.

The external analogue input, or direct address assignment, is used to set the size of the external output torque of the motor shaft, for example, 10V corresponds to 5Nm; when the external analogue is set to 5V, the motor shaft output is 2.5Nm: if the motor shaft load is less than 2.5Nm, the motor is positive; when the external load is equal to 2.5Nm, the motor does not rotate; greater than 2.5Nm causes the motor to stop rotating; greater than 2.5Nm When the external load is equal to 2.5Nm, the motor reverses (usually in case of gravity load).

By adjusting the analogue setting on-the-fly or altering the value of the appropriate address via communication, the CNC servo drive can change the set torque.

The torque setting is changed at any time depending on the winding radius to ensure that the forces on the material do not change with the winding radius in winding and unwinding installations where the forces on the material are very demanding, such as in rapping or fibre pulling equipment, where the torque setting is changed at any time depending on the winding radius to ensure that the forces on the material do not change with the winding radius.

The frequency of the external input pulse defines the size of the rotation speed, and the number of pulses determines the rotation angle, and certain servos can assign values to speed and displacement directly via communication.

The position mode of the ab servo drive is commonly employed in positioning devices because it provides for very precise control of both speed and position. CNC machine tools, printing machines, and other applications are examples.

When the upper control device is controlled by an external PID, the speed mode can also be utilized for positioning, but the position signal of the motor or the position signal of the direct load must be supplied to the upper feedback for arithmetic purposes.

The external loop detection of the position signal of the direct load is also supported by the position mode of ab servo drive, where the encoder at the end of the motor shaft only detects the motor speed and the position signal is provided by the detection device at the direct final load.

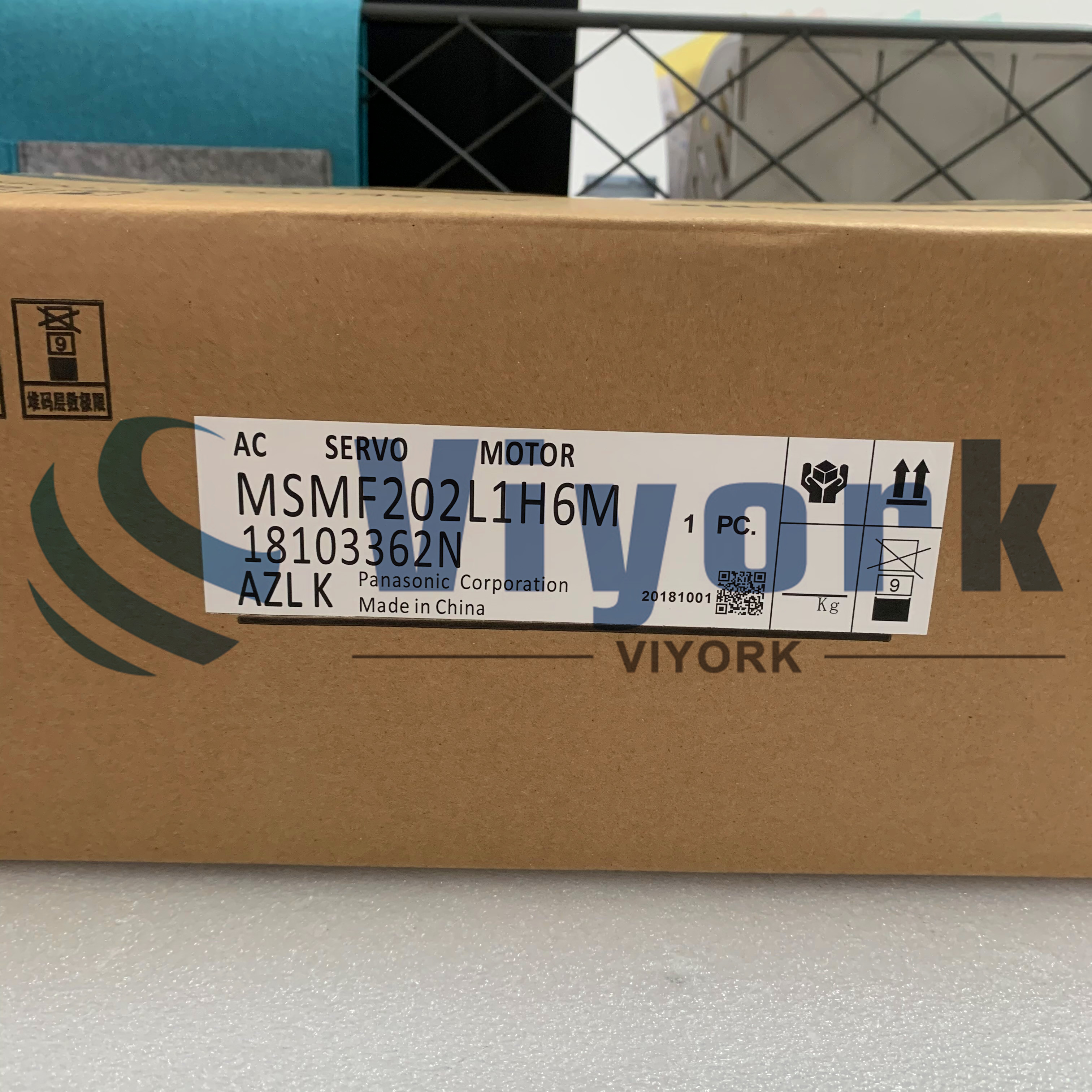

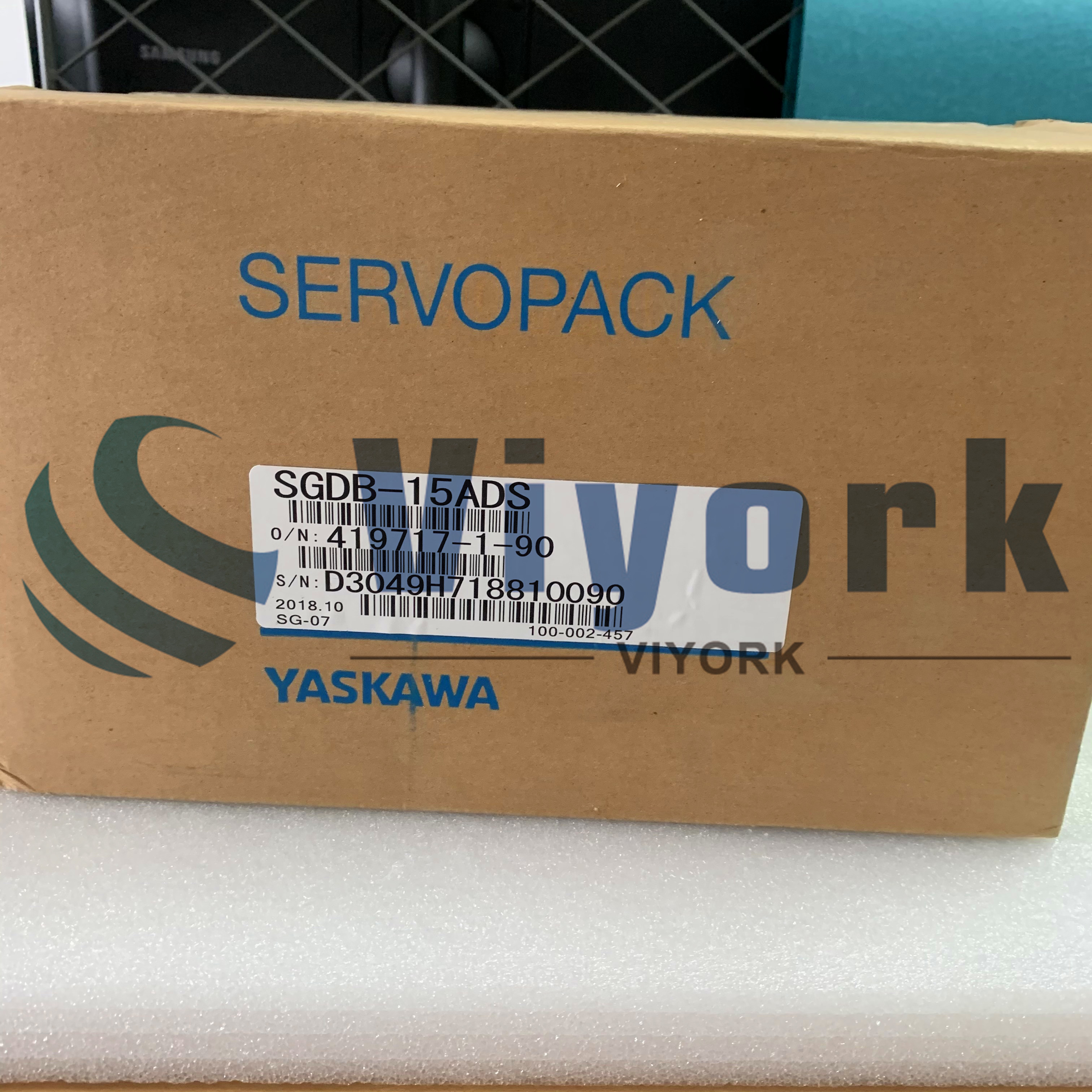

Our company is rapidly increasing its business as a sales and system integration of replacement parts for imported automation systems, thanks to the support of our clients and industry colleagues, as well as the efforts of all of our employees, and our business now encompasses China and the rest of the world. Our ambition is to become one of the world's greatest and most well-known suppliers of industrial automation products. Please do not hesitate to contact us if you have any questions.

Call us on:

Call us on:  Email Us:

Email Us:  1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China

1103, Block C, South Building, Luo Fang Road, Luohu District, Shenzhen, 518001, China